News and Articles

Related Product

Share Article

What are the Applications of Thermal Cooling Pads?

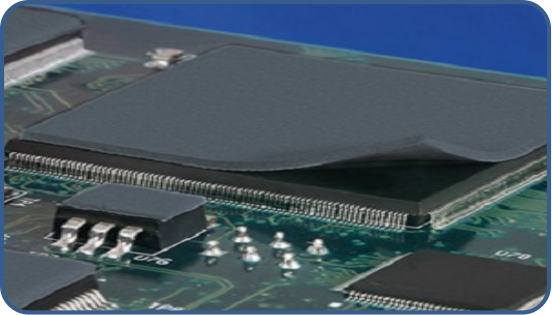

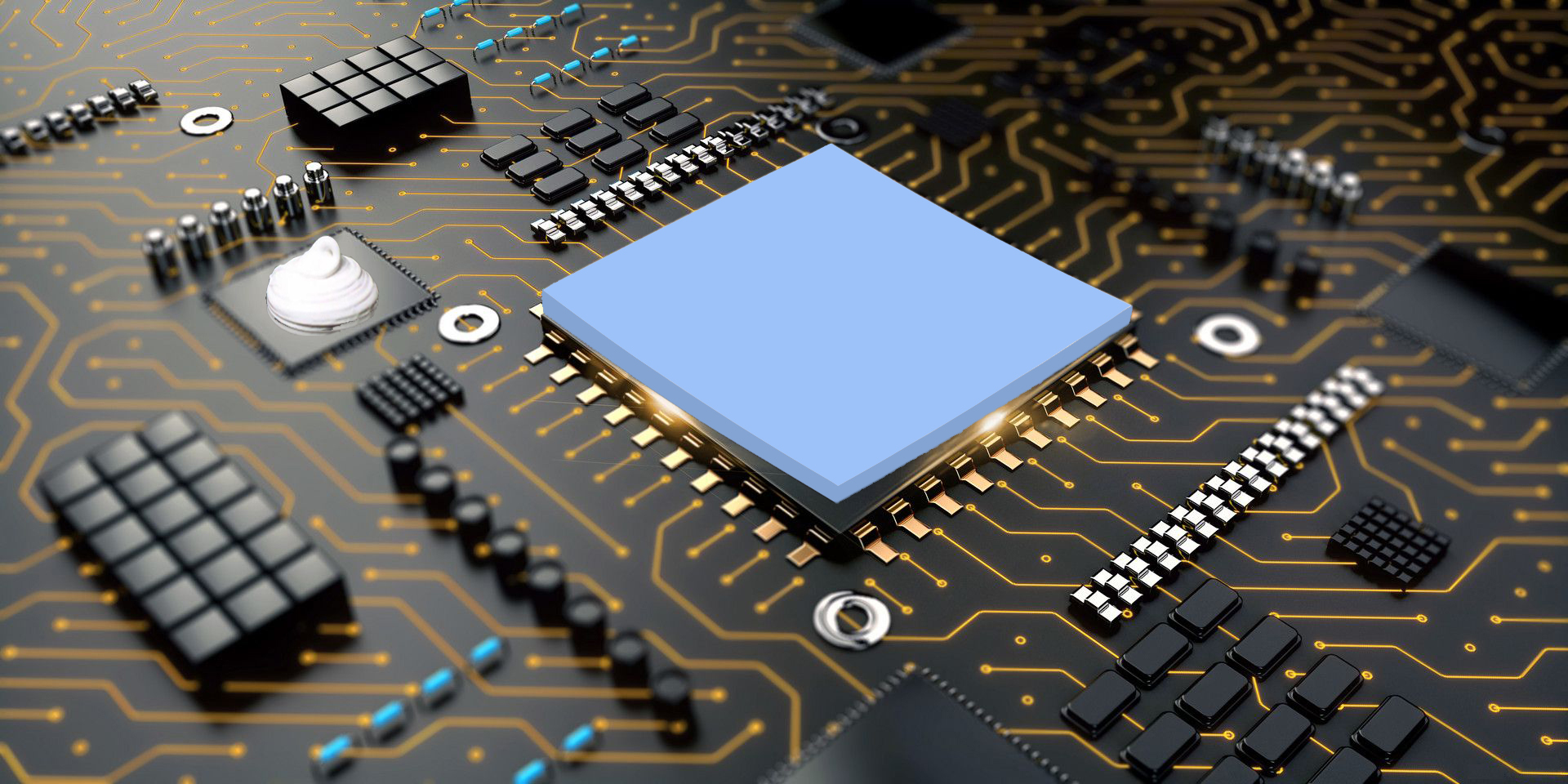

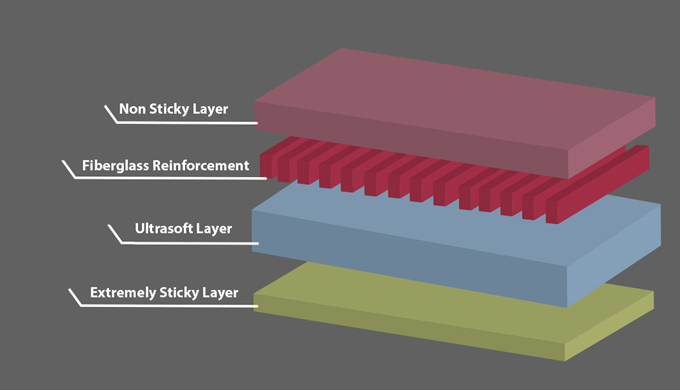

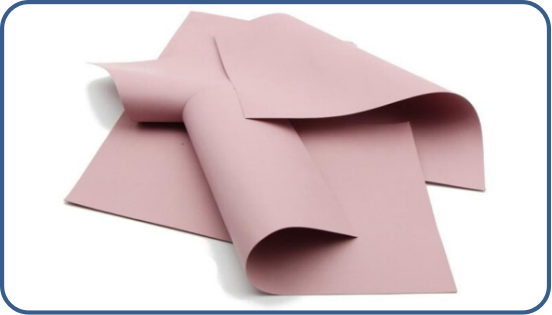

Thermal cooling pads are used in electronic devices and machinery to dissipate heat that is generated by components, such as microprocessors, graphics cards, and power transistors. The primary function of these pads is to transfer heat from the components to a heat sink, which then dissipates the heat into the surrounding air or liquid.

In the field of electronics, with the development of integration and assembly technology, electronic components are also developing in the direction of lightness and smallness, but the operation of equipment parts will generate heat energy, and if the heat energy is not dissipated, there will be excessive heat. High problems affect the performance of the equipment. At this time, it is necessary to use insulating materials with strong thermal conductivity. The quality of thermal conductivity directly affects the service life and stability of the product.

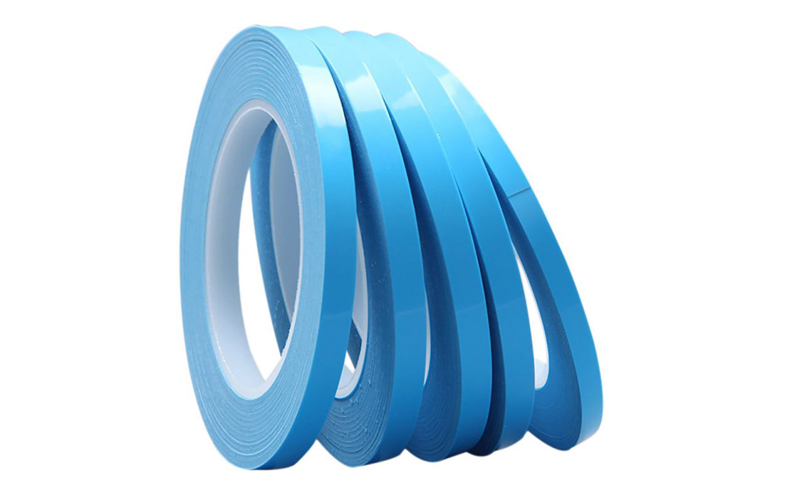

The main uses of thermal cooling pads include:

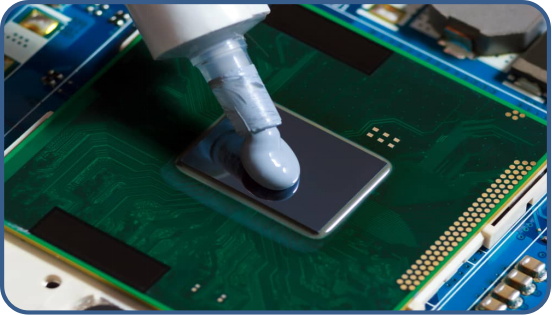

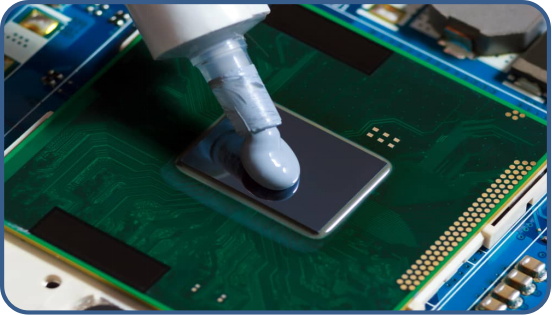

1. Cooling CPU/GPU: Helps to lower the temperatures of the central processing unit and graphics processing unit of a computer or gaming device, which can enhance the operational efficiency and prolong the lifespan of these components.

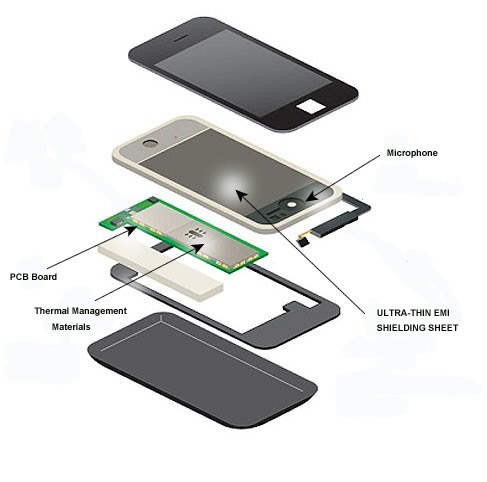

2. Heat dissipation: Thermal cooling pads are used in various electronic devices, including smartphones, laptops, tablets, and servers, to effectively dissipate heat and prevent overheating.

3. Power electronics: In high-power applications, where electrical current can generate a significant amount of heat in power transistors, thermal cooling pads are used to help manage the heat generated.

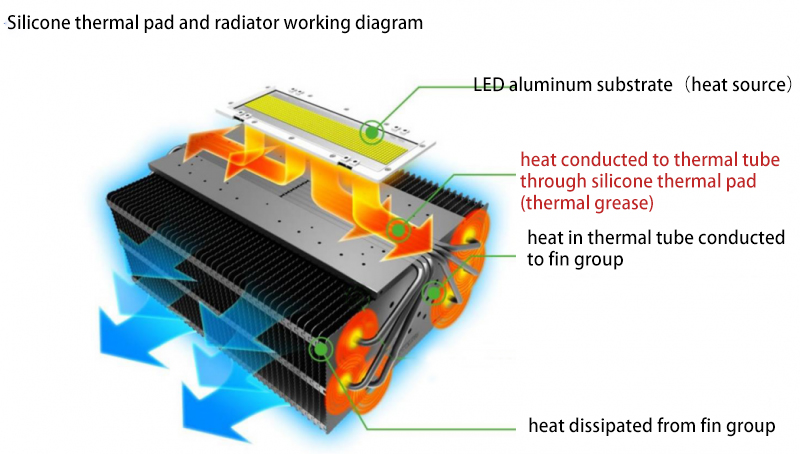

4. LED lighting: In high-power LED lighting systems, thermal cooling pads are used to remove heat generated by the LEDs to ensure longer lifespan and optimal performance.

Overall, thermal cooling pads are vital components that help maintain the performance, efficiency, and longevity of electronic devices and machinery.

In order to solve the problem of product heat dissipation, the initial method is to sandwich a layer of insulating heat-conducting materials between the components and heat dissipation, such as mica, beryllium oxide ceramics and other materials. These materials have certain effects, but the thermal conductivity is not very good, and The price is still high. Due to the better heat transfer performance and relatively low price of thermally conductive pads, the application of thermal cooling pads is becoming more and more extensive.

1. For heat dissipation: thermal cooling pads can be used for heat dissipation of electronic components, computers, electric tools, motors, lamps, cables and automobiles.

2. For sealing: thermal cooling pads can be used for sealing electronic components to prevent the entry of moisture, dust, oil and other pollutants.

3. For insulation: thermal cooling pads has excellent electrical insulation, and can be used for insulation of electronic components to prevent short circuits, etc.

4. Used to suppress noise: thermal cooling pads has excellent noise reduction effect, and can be used for noise reduction of electronic components to reduce noise pollution.

Thermal cooling pads are generally used for thermal management inside electronic products, such as mobile phones, computers, etc. It has excellent thermal conductivity, high temperature resistance, acid and alkali resistance, tensile strength, chemical corrosion resistance and water resistance. Effectively reduce the temperature of the equipment and improve the service life of the equipment. In addition, thermal cooling pads can also be used in other fields, such as aviation, aerospace, vehicles, etc., which can be used to reduce the temperature of automobile and aircraft engines and improve the reliability and stability of the engines.