News and Articles

Related Product

Share Article

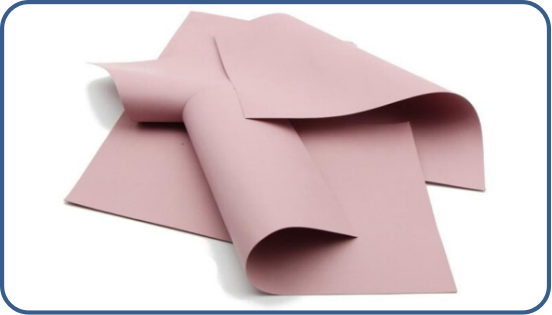

What are silicone free thermal pads?

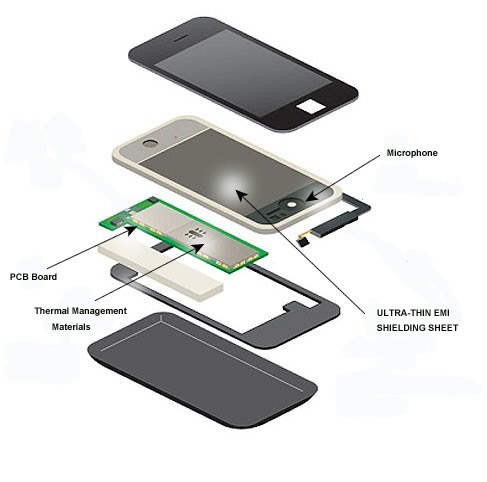

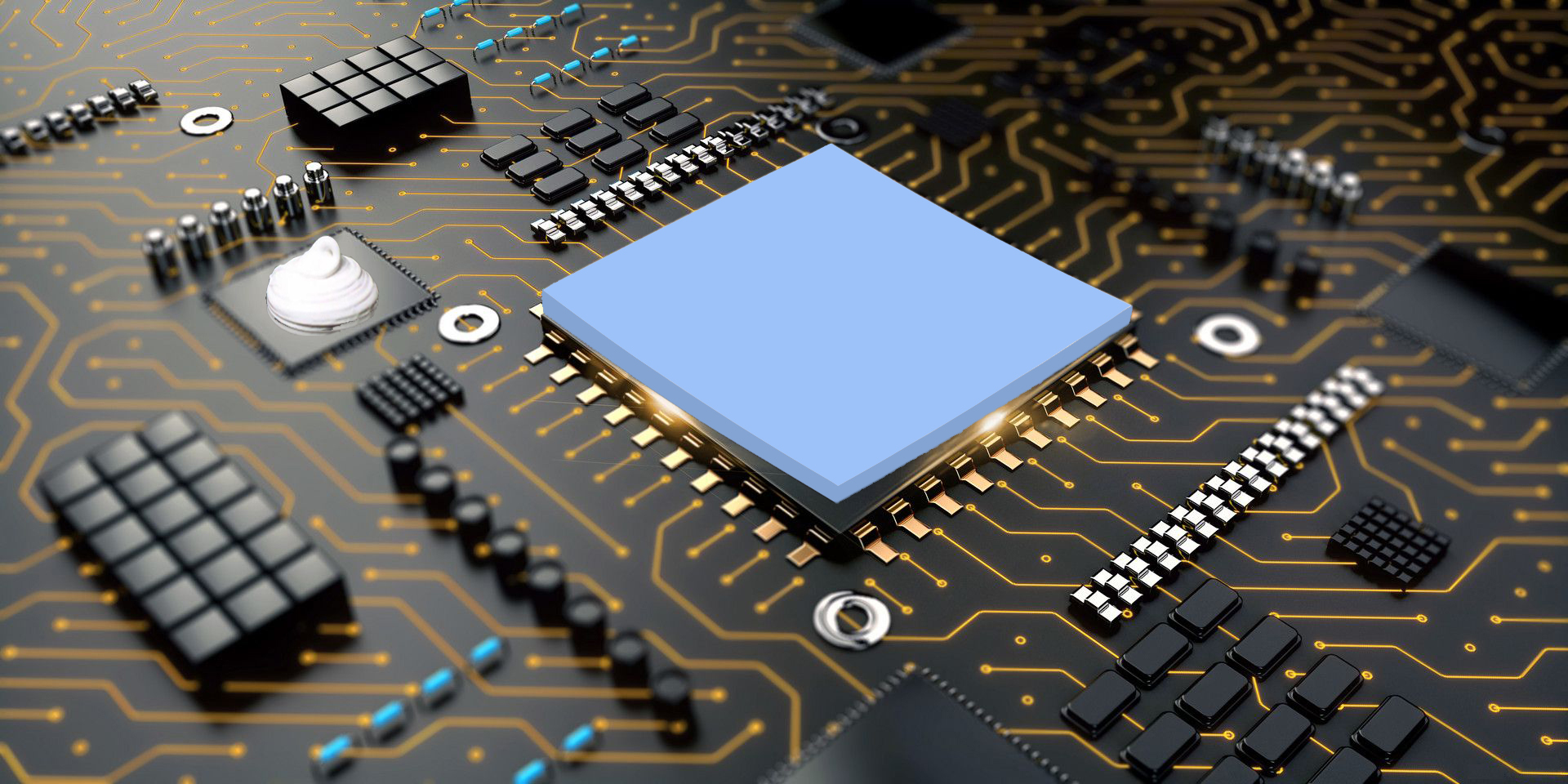

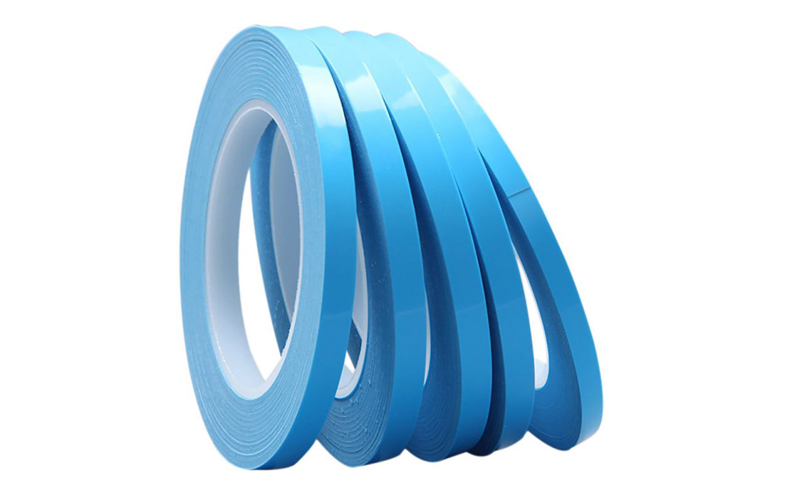

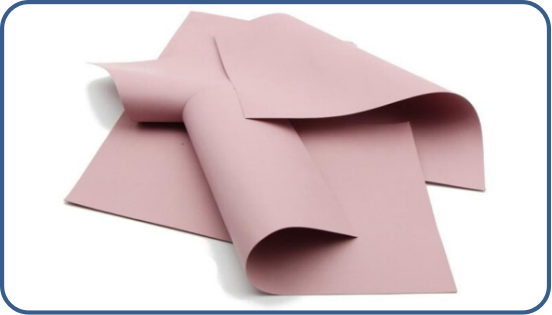

A silicone-free thermal pad is a type of thermal interface material that does not contain any silicone-based compounds. These pads are made up of materials like graphite or ceramic, and are designed to provide high thermal conductivity while avoiding potential compatibility issues with silicone-based materials like certain adhesives or conformal coatings. Silicone-free thermal pads are commonly used in electronic devices such as laptops, smartphones, and gaming equipment to help dissipate heat generated by the components.

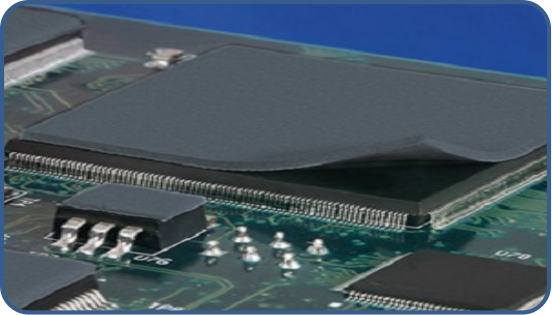

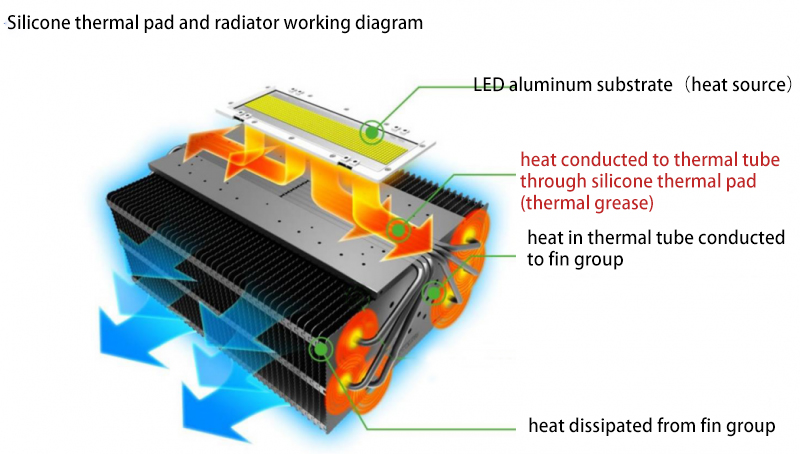

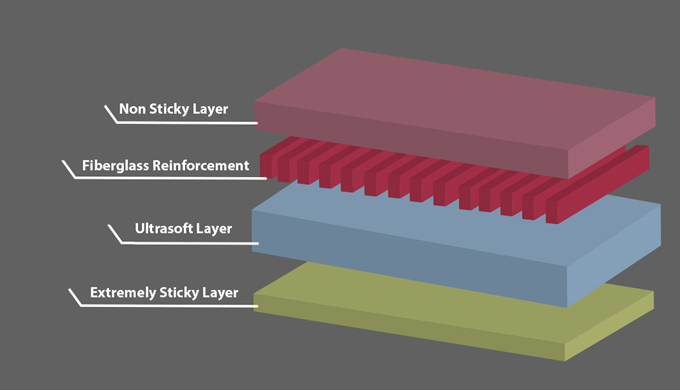

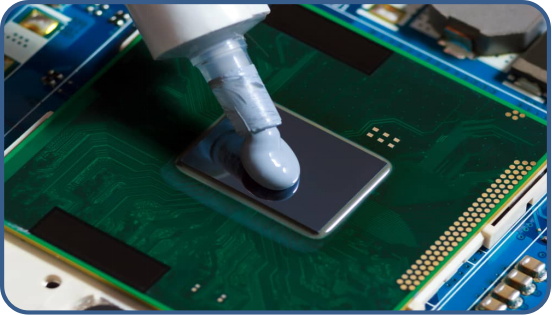

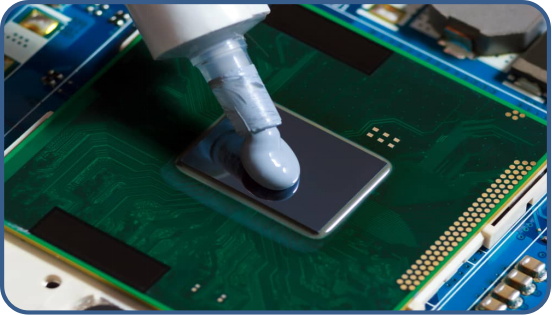

Silicone free thermal pads are thermal interface material that are treated with special resins based on metal oxides and special additives, and are often referred to as non silicon thermal pads, silicone free thermal pads, etc. in the industry. Silicone free thermal pads is a soft, silicone free gap filling thermally conductive material with high thermal conductivity, low thermal resistance, high compressibility, controllable hardness, and no silicone small molecules in the pressurized and heated operating environment volatile, to avoid adsorption on the PCB board due to the volatilization of small siloxane molecules, which indirectly affects the performance of the body. The silicon free thermal pads acts on the gap between the heat source and the radiator/housing. Due to its good softness, it can effectively remove the air at the interface, reduce the thermal resistance of the interface, and improve the thermal conductivity.

The material of the silicone free thermal pads does not contain any silane forming molecules at all, so there is no need to worry about circuit failure caused by the precipitation of silicone oil or the volatilization of siloxane. It has very good tensile strength and elongation, and at the same time inherits the high thermal conductivity of thermal silicone pads. Performance and good electrical insulation properties.

silicone free thermal pads, compared with traditional silicone thermal pads, the obvious advantage of silicone free thermal pads is that the content of low molecular siloxane is zero, which solves the problem of silicone oil volatility that many engineers worry about. After long term repeated tests, the low-molecular weight siloxane did not precipitate, which is much better than the silicone thermal pads used before, and the thermal conductivity is also 3.0w/m.k. Not only the temperature is lowered better, but also the PCB board can be removed after rework. Also very clean with no dirt on it.

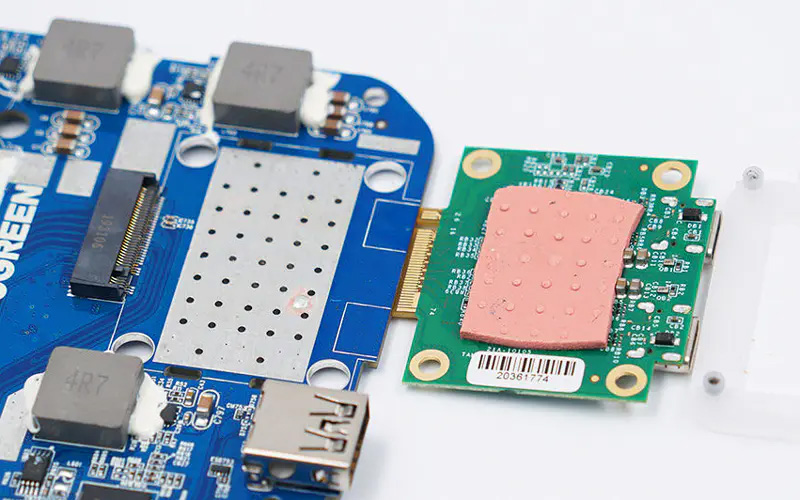

Our silicone free thermal pads are very soft which is beneficial for reducing applied stress on the PCB and lowering the thermal resistance. That aid in the dissipation of heat from intended targets to cooler surface areas within an electronic device. They are often used to cool SSD (solid state drives) or can be attached to the bottom of heatsinks, to act as a thermal interface bridge between surfaces to accommodate thermal conductivity to alleviate over heating of an electronic device.