News and Articles

Related Product

Share Article

All Thermal Pad Materials FAQ

We find science-enabled, thermal interface material sustainable solutions for our customers, always managing our businesses to protect the environment and preserve the earth's natural resources. You will find all the frequently asked questions about thermal conductive materials.

Q: What is a thermal pad?

A: A thermal pad is a type of thermal interface material used to transfer heat from a heat-generating component to a heat sink or another surface, helping to dissipate heat more efficiently and prevent overheating.

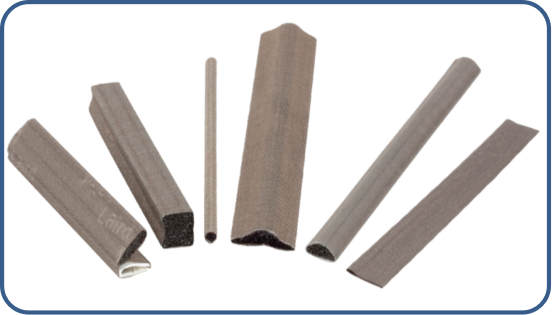

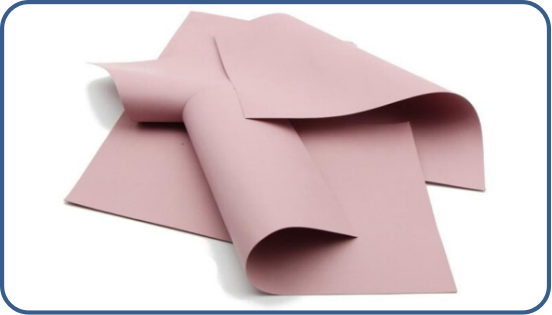

Q: What are thermal pads made of?

A: Thermal pads are typically made of materials such as silicone, graphite, or other thermally conductive materials.

Q: How do thermal pads work?

A: Thermal pads work by filling in the microscopic gaps between the heat-generating component and the heat sink or other surface, creating a more direct path for heat transfer. This helps to increase the efficiency of heat dissipation and prevent overheating.

Q: What are the benefits of using a thermal pad?

A: The main benefits of using a thermal pad include improved thermal conductivity, reduced thermal resistance, and increased thermal stability. This can help to increase the lifespan of electronic components and prevent damage from overheating.

Q: How do I choose the right thermal pad?

A: The choice of thermal pad will depend on the specific application and the heat-generating component being used. Factors to consider include thermal conductivity, thickness, and size, as well as any specialized features or properties the thermal pad may have, such as electrical insulation, flame resistance, or compatibility with certain materials. It is also important to consider the operating conditions and temperature range of the application to ensure the thermal pad can perform reliably over time.

Q: Are thermal pads adhesive?

No, thermal pads are not adhesive. You will need a proper mounting to hold the thermal pad with a heatsink.

Q: Are thermal pads electrically conductive?

Absolutely not! thermal pads are non-electrically conductive.

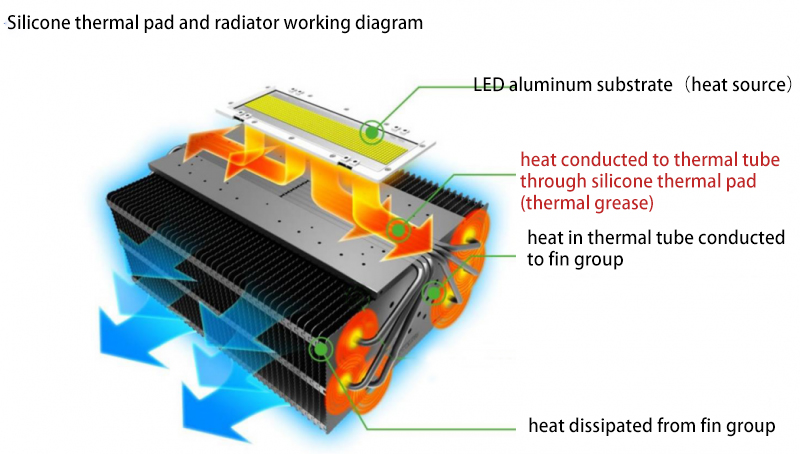

Q:What is thermal grease?

Thermal grease (also known as thermal grease or thermal paste) provides heating agent for CPU heat dispersion devices to use. the main raw material of the thermal silicon is additive heat resistance, excellent thermal conductivity, synthetic thermal organic silicon-like composite.

Thermal grease High thermal conductivity, excellent thermal conductivity, good electrical insulation (just for thermal silicone), excellent working temperature, favorable usability, very low consistency and good construction performance.

Q:Is it ok to put thermal paste on thermal pads?

No, it is not recommended to put thermal paste on top of thermal pads.

Thermal paste should only be used when there is a gap between the heat sink and the component. If you use thermal paste on top of a thermal pad, it will fill in the pores of the pad and reduce its ability to dissipate heat.

Both components fulfill a different purpose and are not complementary. It is best to use them separately to get the most effective cooling for your system.

Use a thermal paste if there is no gap between the component and heatsink. The thermal paste is applied on the surface of the component where it touches the heat sink .

Q: How do I know if my GPU thermal pad is bad?

Using a program like HWInfo lets you monitor temperatures. Thermal pads may be harmful if your GPU memory temperatures are unusually high when running a benchmark or stress test, even at max fan speed.

Q: Should I replace thermal pads on my GPU?

Changing thermal pads is not recommended unless you notice high memory temperatures or frequent crashes. As the thickness of these pads varies by small amounts, replacing them with new ones of the wrong size and thickness can worsen it. However, those running GPUs 24x7 in dusty environments need to replace thermal pads periodically to reduce the chances of failure.

Q: Is stacking thermal pads OK?

Stacking is ok, but will reduce thermal pad performance. Also on GPUs you will want the correct thickness. Having uneven/wrong pad sizes can cause the heatsink to not seat correctly and you can get higher temps than stock.

Q: Does thermal pads really working?

While a thermal pads is not as compressible as a thermal paste, the range of available materials means thermal pads are extremely effective with any substrate. Additionally, thermal pads maintain their initial performance over the long-term since they are not subject to the same types of degradation as thermal grease.

Q: What thickness thermal pad should I use?

Ideally, you should use the thinnest thermal pad that you can with the device. Start with a 2mm thermal pad, and if it has an indentation from the heatsink go down a size of thickness. The material that you use also matters, as some materials dissipate heat better than others.

Although the thermal conductivity belongs to the physical properties of the silicone gasket, it only depends on the material of the silicone gasket itself, and will not be affected by the thickness, current situation, etc.

However, the thermal resistance becomes larger with the increase of the thickness, and finally directly affects the heat conduction effect.

Therefore, considering only the heat conduction effect, in the case of the same thermal conductivity, it is actually better to be thinner.

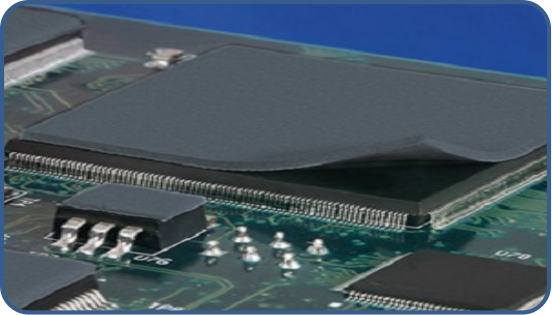

Q: Should I put thermal pads on my cooler?

Thermal pads are heat-conducting media that fill the air gap between heating components of electronic products and heat sinks or metal casings. The flexible and elastic characteristics of thermal pads allow them to be used to cover very uneven surfaces. Heat is conducted from the entire PCB to the metal housing or diffuser, which improves the efficiency and lifespan of heat-generating electronic components.

Q: Can I put a thermal pad between the laptop motherboard and the SSD?

Under normal circumstances, solid-state hard drives do not need to be pasted with thermal pads, because although the hard drive will generate heat when it is working, its heat is negligible compared with the CPU of the graphics card.

Q: How can I request thermal interface material sample?

Please contact to sales@fine-materials.com for your request. Thermal interface material sample will take a 5 to 10 business days for shipping.

Q: What is proper thermal interface material products for me?

Before you make an order, please let us know the type of thermal interface material, application purpose, specs or any other information you have. Our specialist will suggest you what product is appropriate.

Q:How often should you replace thermal paste?

As per reports the factory supplied thermal paste is good for about 1~1.5 years at most and then begins to degrade in performance which leads to the heating of the processor of the laptop.

So it is said that as a precautionary measure you should change the thermal paste to a better quality one with time so as to keep the hardware health of the laptop in peak condition for a longer period of time.

Q: The thicker the epoxy is the cooler the device will run?

The 0.03 W/m*K figure doesn't take convection into account, which will become the dominant form of heat transfer if there is adequate room for it to occur (at normal electronics operating temperatures). As the gap increases, the thermal compound will become limited by the thermal gradient inside the compound while air cooling will more closely approximate free-air convection conditions. You will probably have to perform a detailed analysis to determine which is better. There are of course exceptions, but thermal potting compound should be chosen primarily because you need potting for your application. If you just need to get rid of heat, there are plenty of other options that are easier to work with - thermal pads, thermal grease, heatsinks, heatpipes - that don't make your device impossible to repair and don't expose you to e.g. triethylenetetramine.

Q: What is the allowable error in the mixing ratio of the thermally conductive gel?

A and B component materials should be mixed in the specified mixing ratio within a tolerance of +/- 5% to ensure material properties. If there are light streaks or marbling in the material, it indicates insufficient mixing.

Q: What is the test standard used for Lin-tech thermal conductivity?

Lin-tech adopts ISO22007-2 standard

Q: How is viscosity measured?

Due to the thixotropic characteristics of most Gap Fillers, special consideration should be given to the test method(s) used to determine viscosity of these materials. Because the material viscosity is dependent on shear rate, different measurement equipment testing under varying shear rates will produce varied viscosity readings. When comparing apparent viscosities of multiple materials, it is important to ensure that the data was generated using the same test method and test conditions (therefore the same shear rate).

Q: How does the new energy power battery dissipate heat?

Type 1: Natural heat dissipation

It is to use a high thermal conductivity material to make a heat sink (the thermal conductive silicone sheet with a back silicone cloth has a wide range of applications), which is connected to the power battery pack to take away the heat generated by the battery when it is working, and naturally dissipate it into the air. This cooling method is relatively passive, and the cooling effect is not very good, but the cost is lower.

Type 2: Air-cooled heat dissipation

On the basis of natural heat dissipation, a fan with heat sink is installed to increase the heat dissipation area and air circulation speed, so that the heat inside the power battery pack can be quickly dissipated.

1. A cooling fan is installed at one end of the power battery pack, and ventilation holes are left at the other end to accelerate the flow of air between the gaps of the cells and take away the high heat generated by the cells during operation;

2. Add a thermally conductive silicone sheet to the top and bottom of the electrode, so that the heat that is not easily dissipated at both ends is conducted on the metal shell to dissipate heat through the thermally conductive silicone pad. Very good protection.

Type 3: Liquid cooling

It is to add a set of liquid cooling radiator to the power battery pack and form a circuit. After the heat generated by the battery is transferred to the liquid in the radiator, the liquid generates convection due to the heat transfer, so that the liquid can flow by itself in the circuit, thereby carrying heat.

1. The heat of the battery cell is transferred to the liquid cooling tube through the thermal conductive silicone sheet, and the heat is taken away by the principle of thermal expansion and contraction of the cold liquid, so that the temperature of the entire power battery pack is unified, and the strong specific heat capacity of the cold liquid absorbs electricity. The heat generated when the core is working makes the entire battery pack operate within a reliable temperature;

2. The thermally conductive silicone sheet has good high resilience and insulation performance, which can avoid the problem of vibration and friction damage between the cells and the hidden danger of short circuit between the cells. It is a good auxiliary material for the water cooling scheme.

Type 4: Refrigeration and heat dissipation

It is to use the process of gas-liquid change of the refrigerant as a heat exchange medium to rapidly decrease the temperature of the power battery. This method has the best heat dissipation effect and the highest cost.

At present, the power batteries of new energy vehicles are mostly air-cooled and liquid-cooled.

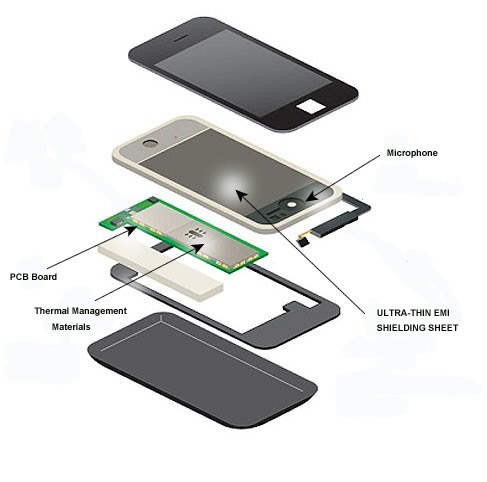

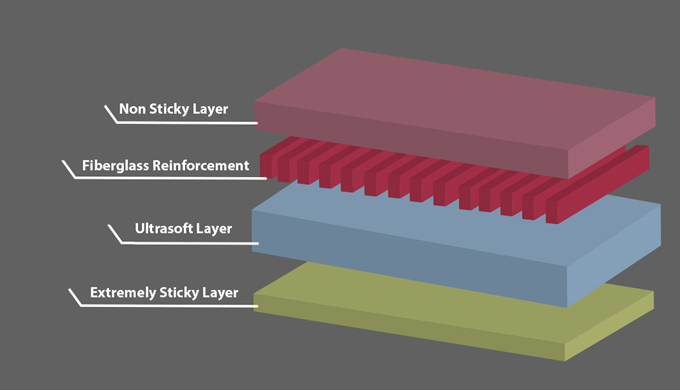

Q: What is a electrically insulating thermal sheet?

The electrically insulating thermal sheet is a sheet of cloth-like thermally conductive insulating material produced by special processes such as coating and casting as the base material of silica gel and glass fiber (or polyimide film, English Polyimide film, referred to as "PI film"). product. Because of its excellent thermal conductivity, insulation, high dielectric constant, low thermal resistance and easy assembly, it is widely used in electronic appliances and other industries.

Q: Why does the thermal grease fail during use?

This situation is mainly due to the precipitation of silicone oil in the thermal grease. Due to the volatilization of silicone oil, the thermal grease is not uniformly distributed, and there will be air gaps in the middle, causing the thermal grease to reduce its heat dissipation effect and become invalid. We can use the degree of oil separation as an index to evaluate the heat resistance and stability of thermally conductive silicone grease: good quality thermally conductive silicone grease has a very low degree of oil separation and tends to zero.

Q: What does your company's thermal pad have weak adhesiveness?

Our thermal pad product itself has the natural characteristics of silicone rubber, has a weak viscosity, and can be easily assembled and applied. This kind of self-adhesiveness is easier to peel off than the back glue, preventing tearing.

Q: What test standard does your company use for thermal conductivity?

At present, our company adopts ASTM D5470 standard

Q: How to choose the thermal conductivity of thermal grease?

The choice of thermal conductivity is related to the application environment, especially the power of the heat source, the volume of the radiator, and the temperature difference between the two sides of the interface. In general, in desktop processor applications, the thermal conductivity of thermal grease is 3.0w~4.0w/m·K, the higher the effect, the better; in the application of power MOSFET, it is usually recommended to choose 3.0w/ For thermal grease of about m·K, if the working current of IGBT devices is as high as several hundred amperes, it is recommended to use 5.0w/m·K.

Q: What is the insulation performance of thermal grease?

Since thermal grease is a liquid interface material, and the application is relatively thin (usually about 0.2-0.3mm), its insulation performance during use is usually not considered. If there are specific requirements for the insulation strength, it can be matched with a ceramic thermal pad to conduct heat Use insulating silicone cloth.

Q: Why are wettability and compliance an important feature of thermally conductive gaskets?

A good caulking material has good wettability and compliance, and can reduce the thermal resistance caused by voids. Thermally conductive gaskets with these two properties can well complete the gap filling function, they can be well absorbed on the surface, and effectively reduce the thermal resistance.

Q: Details the hardness of the thermal pad?

Thermal pad have a wide range of uses, such as: filling cooling devices, communication hardware, automotive control units, LED lighting equipment, PDP displays, etc. In these applications, the thermal pad will produce a certain amount of compression to bridge the gap to achieve good thermal conductivity. The hardness of the thermal pad directly reflects the hardness of the thermal pad, and its size will affect the compression performance of the product, which is a very important parameter. Many people have questions about the hardness when choosing a thermal pad, so I will introduce the hardness of the thermal pad.

1. What is the concept of hardness?

Hardness is a mechanical performance index that various mechanical parts and tools must have. It is used to characterize the hardness of the material and refers to the ability of the material to resist local deformation, especially plastic deformation, indentation or scratches.

2. What is the hardness of the thermal pad?

As different test methods are specified, there are different hardness standards. Various hardness standards have different mechanical meanings and cannot be directly converted to each other, but they can be compared through experiments. Common hardness is classified according to the test method: scratch hardness, indentation hardness, rebound hardness. According to the specific hardness name classification: Rockwell hardness, Brinell hardness, Leeb hardness, Shore hardness and so on. According to the standard ASTM D2240 "Standard Test Method for Testing the Hardness of Rubber with a Hardness Tester", the thermal pad uses Shore hardness to express its hardness. The corresponding measuring instrument of Shore hardness is Shore hardness tester, which is mainly divided into three types: Type A, Type C and Type 00. The measurement principle is exactly the same, the difference is that the size of the stylus, especially the tip diameter, is different, type 00 is the largest and type A the smallest. Shore A hardness tester is suitable for measuring harder thermally conductive gaskets; Shore 00 hardness tester is suitable for measuring softer thermally conductive gaskets. Shore hardness belongs to indentation hardness. The test method is to insert the measured material with a Shore hardness tester. The pointer on the dial is connected to a needle through a spring, and the needle is pierced into the surface of the object to be tested. The value displayed on the dial is the hardness. value.

Q: What is thermal resistance?

In the thermal conductivity industry, thermal conductivity is an important parameter reflecting the thermal conductivity of materials. However, in practical applications, it is often not enough to use thermal conductivity alone to assess whether the product is applicable. We often need to introduce another parameter (thermal resistance or thermal impedance) to help judge.

The definition of thermal resistance is the ratio between the temperature difference between the two ends of the object and the power of the heat source when heat is transferred to the object. It can be understood as the resistance encountered by heat on the heat flow path, reflecting the size of the medium or the heat transfer capacity between the mediums, and indicating the size of the temperature rise caused by 1W of heat, in K/W or °C/W. A simple analogy can be used to explain the meaning of thermal resistance. Heat exchange is equivalent to current, temperature difference is equivalent to voltage, and thermal resistance is equivalent to resistance.

At present, the main measures to reduce contact thermal resistance are:

1. Increase the pressure on the contact surface between objects to deform the protrusion on the object interface, thereby reducing the gap and increasing the contact surface.

2. Fill the gap between the two objects with the thermal conductive material, and try to exhaust the air, such as using thermal pads.