News and Articles

Related Product

Share Article

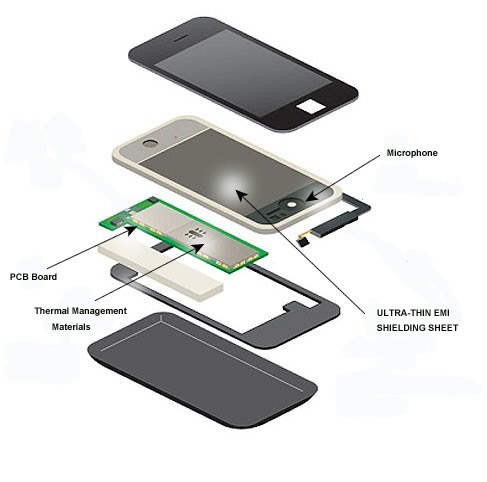

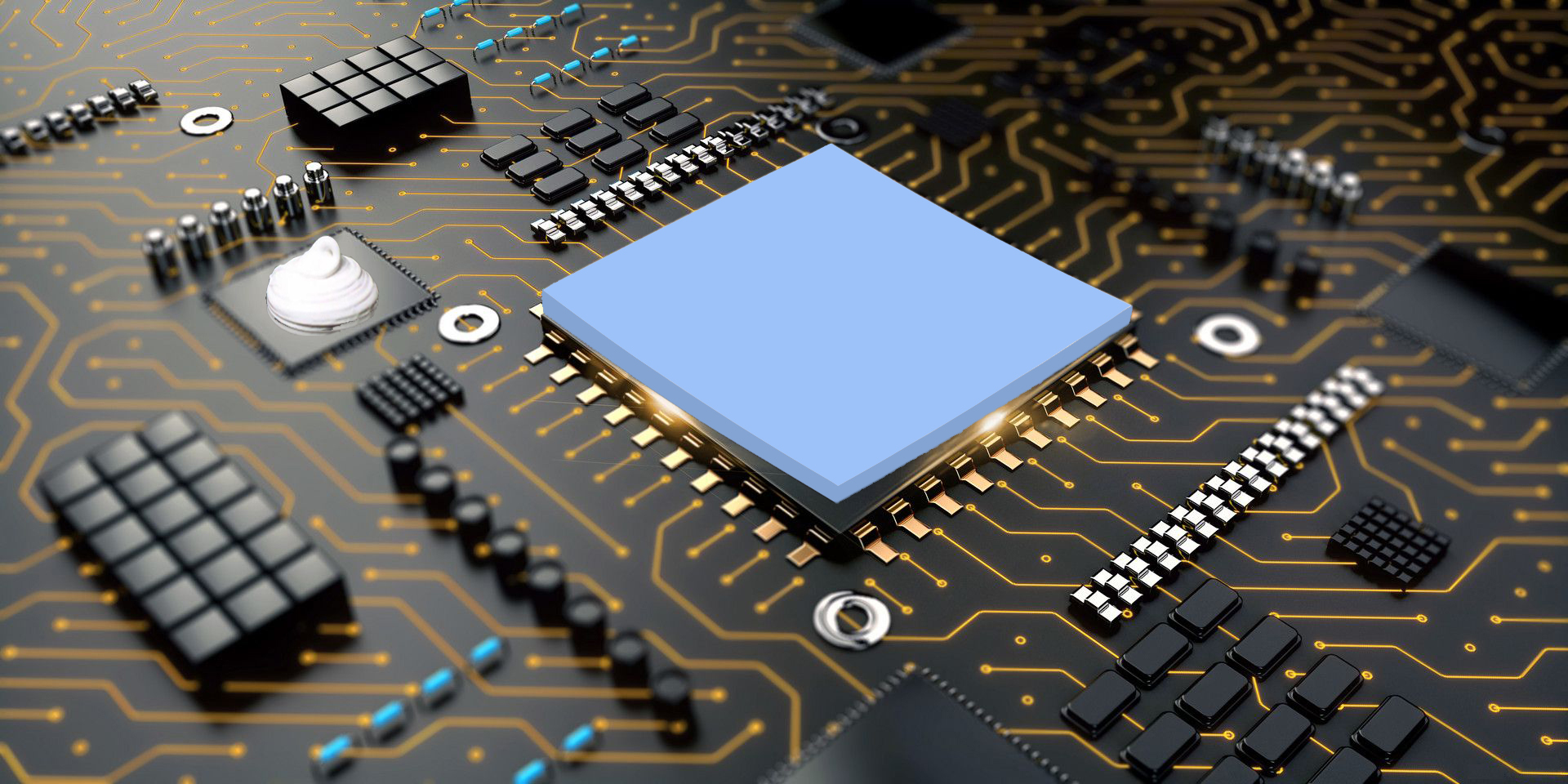

Choosing Thermal Interface Materials for Electronics Cooling

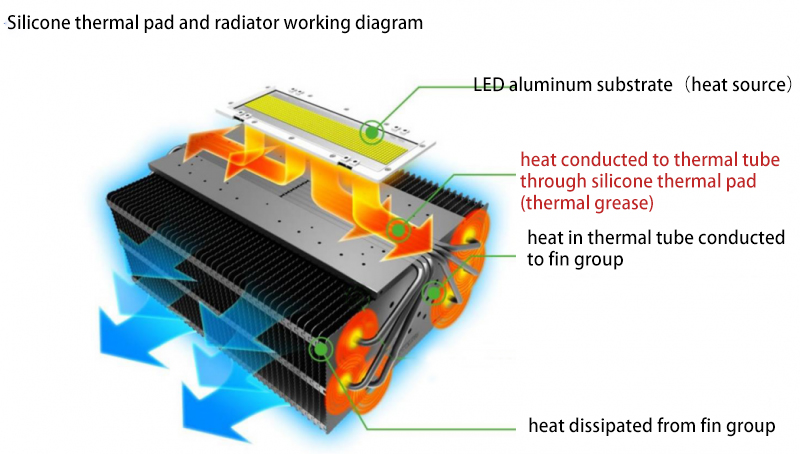

With the continuous increase of the integration density and power density of electronic appliances, the rise of high-power LEDs, etc., electronic devices will release a lot of heat when they are working. Poor thermal conductivity will cause the temperature of the electrical working environment to rise sharply, affecting the operation stability of electronic devices. It even causes damage to the components. If no positive measures are taken, they will be "burned out" by the excess heat released by themselves in minutes. It is said that the reliability of electronic components will drop by 10% for every 2°C increase in temperature.

Where are thermal interface materials used?

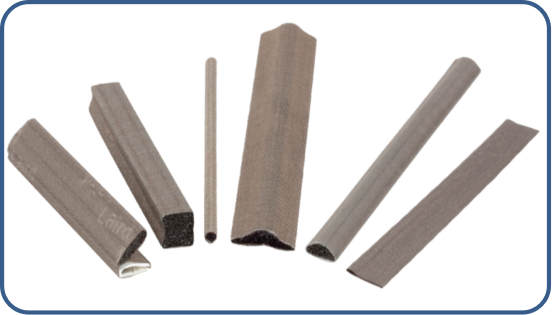

thermal interface materials

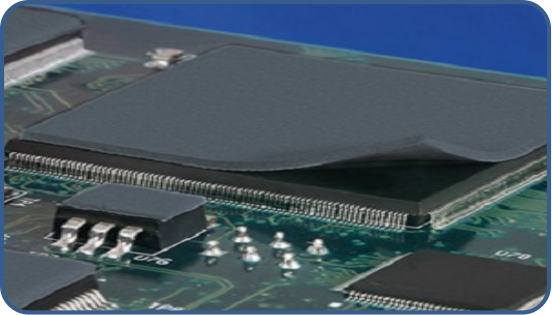

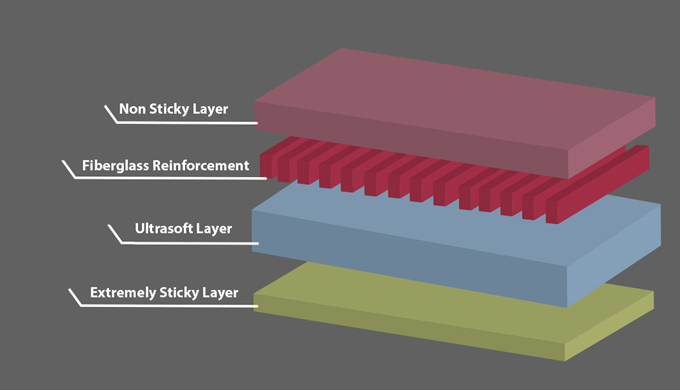

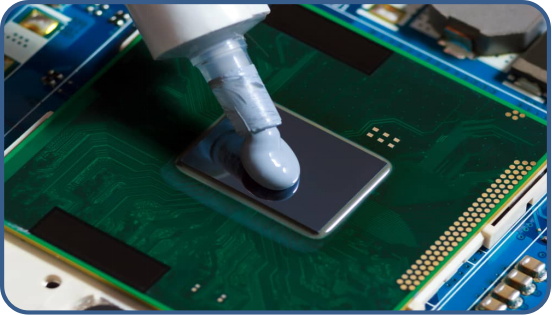

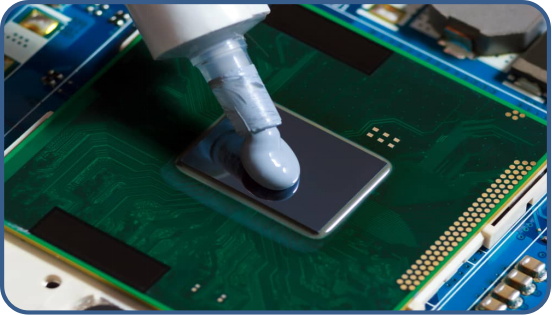

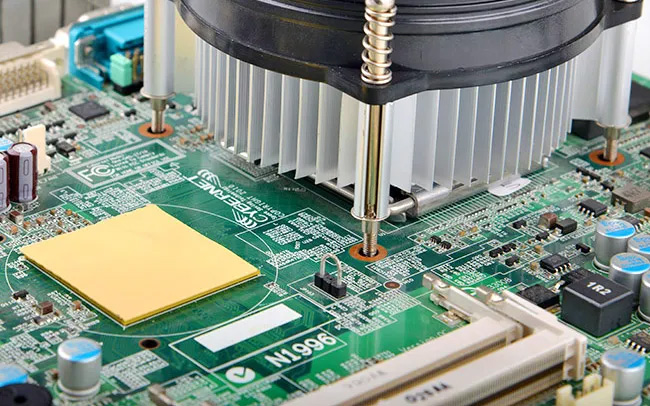

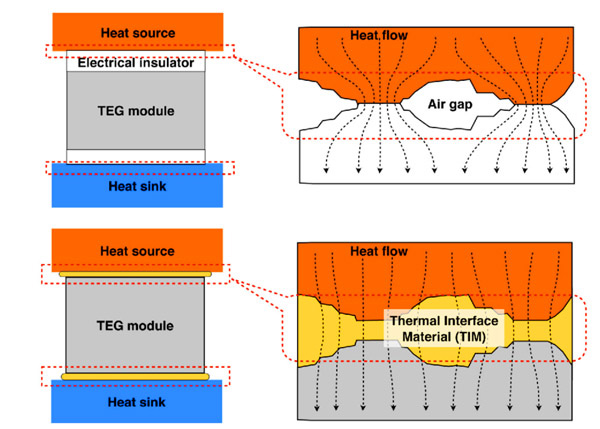

Thermal Interface Materials (TIM) is a filler used between two materials and is an important bridge for heat transfer. When two materials are joined to each other, whether it is the same material or two different materials, even if the surface of the material is very flat or a large fastening pressure is applied, it is still impossible to achieve close contact, only partial contact, and the middle must be fixed. There are still many fine voids or holes.

The air in the gap is a heat transfer medium with poor thermal conductivity, which will hinder the path of heat conduction and increase thermal resistance. Therefore, it is necessary to fill a thermal interface material between the two bonding materials to fill the gap, improve heat transfer efficiency, and reduce thermal resistance. It is a widely used and very important material.

Thermal interface materials are mainly used to fill the gap between the contact surfaces of two materials and reduce thermal resistance. Therefore, the thermal conductivity K is one of the important characteristics for evaluating thermal interface materials. The thermal interface material should have the following basic characteristics: compressibility and softness, high thermal conductivity, low thermal damping, surface wettability, good thermal cycle stability and so on.

When it comes to choosing thermal interface materials for electronics cooling, there are several factors to consider:

1. Thermal Conductivity: The thermal conductivity of the material will determine how effectively it can transfer heat from the heat-generating component to the heat sink. Generally, higher thermal conductivity is better for this purpose.

2. Compressibility: The thermal interface material must be able to fill gaps between the heat-generating component and the heat sink to ensure good thermal contact. A material that is too rigid can lead to insufficient contact and poor cooling performance.

3. Durability: The material should be able to withstand the operating conditions of the electronics it is being used in, such as temperature and vibration.

4. Electrical Conductivity: In some applications, the thermal interface material may come into contact with electrical components. In these cases, it is important to choose a material that is non-conductive to avoid short circuits.

5. Ease of Application: The material should be easy to apply to the heat-generating component and heat sink while also being compatible with any adhesives or fasteners used in the assembly process.