News and Articles

Related Product

Share Article

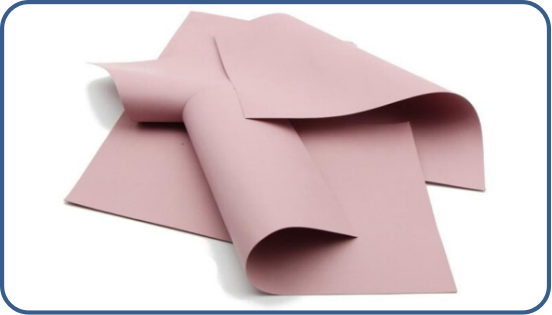

Seven Steps-How to use the thermal conductive silicone Pad

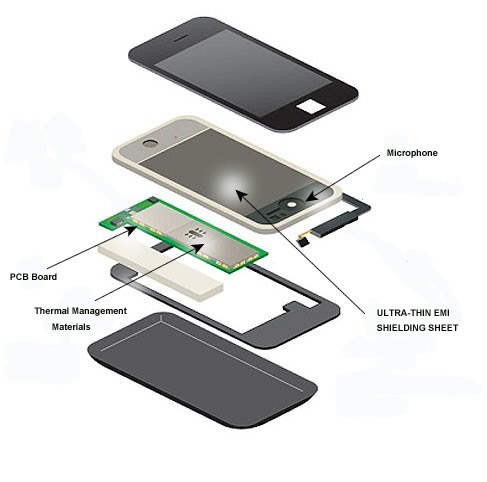

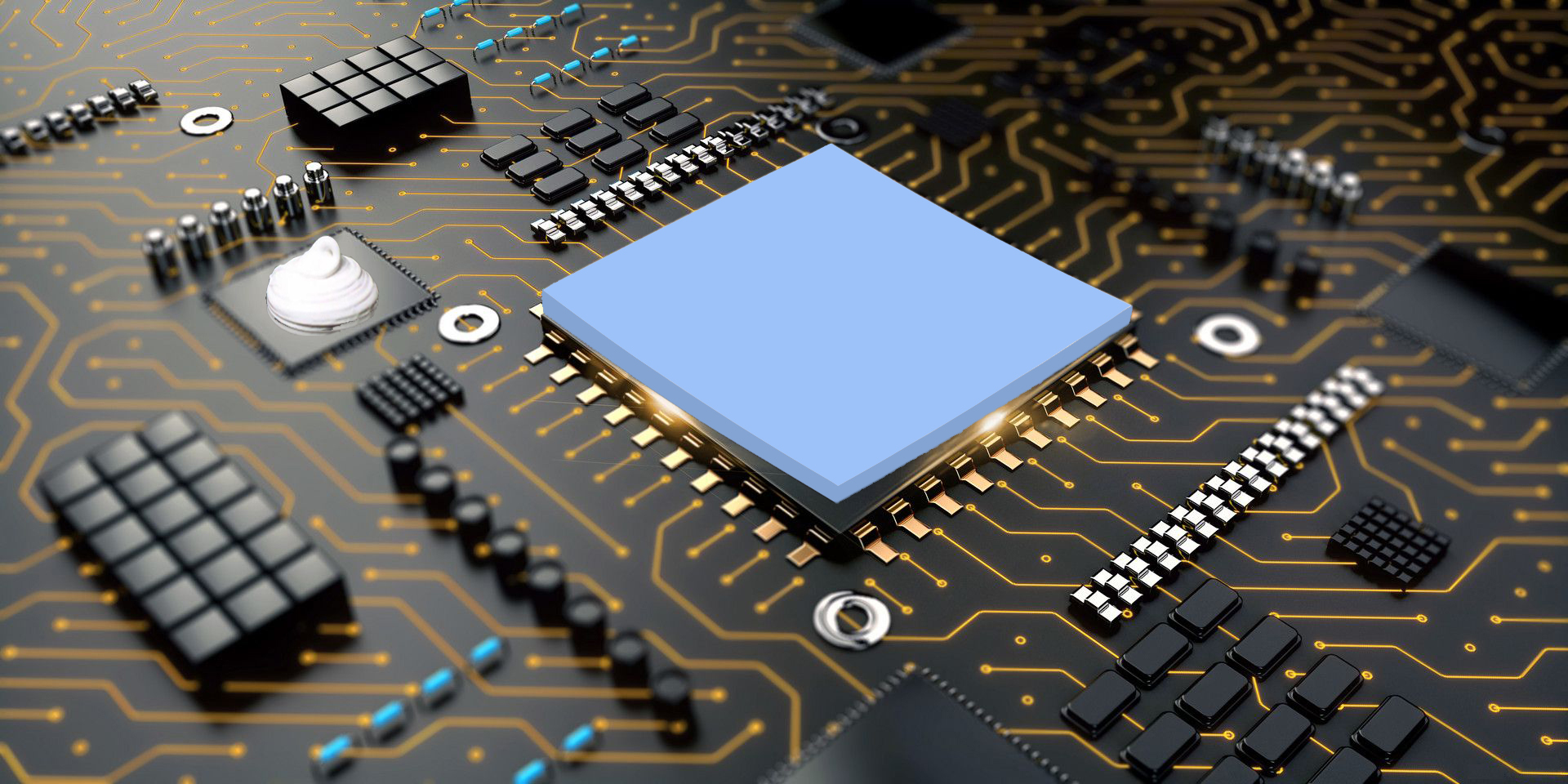

With the rapid development of the electronics industry,Guest Posting high thermal conductivity silicone film has brought great help to the industry. As the height integration and functional requirements of product chips increase, there is a growing demand for smaller sizes. Therefore, heat has become a necessary subject and a daunting challenge for many engineers, and thermal conduction-related technologies have been increasingly emphasized with the development of the electronics industry.

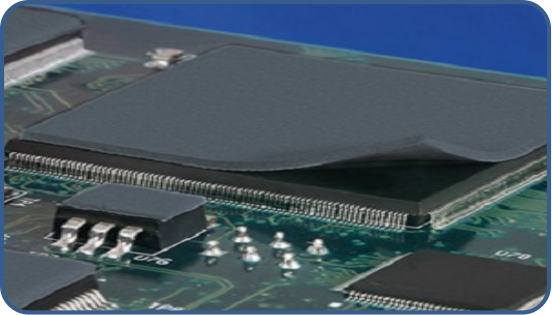

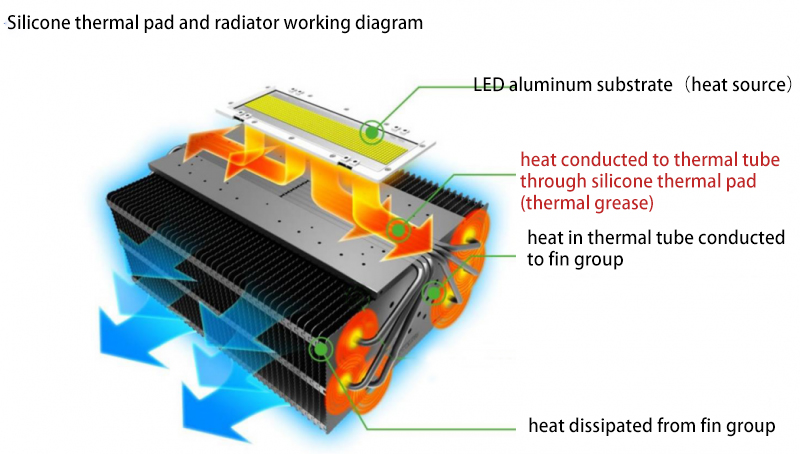

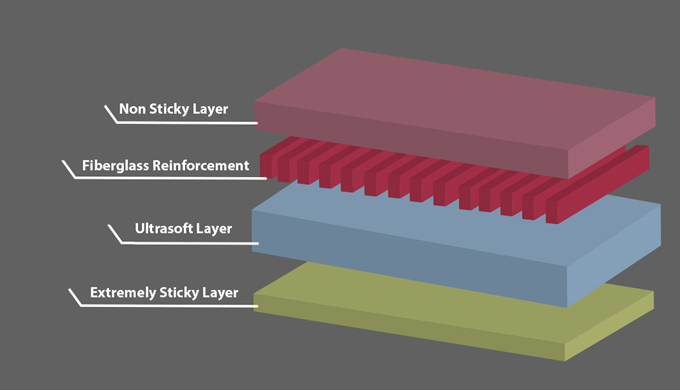

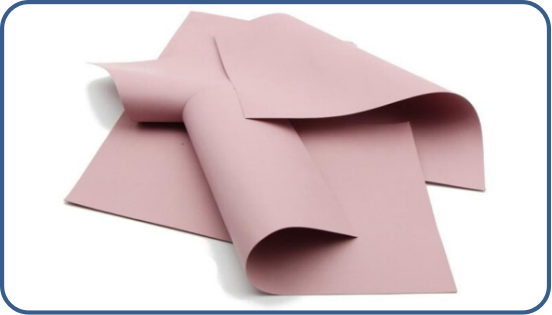

In general, the main function of thermal conductivity silicone film is to fill and conduct heat, and it does not have a heat dissipation function itself. This is because the mating surfaces between the heat source and the heat sink are often uneven, and direct contact involves a large amount of air, which is a poor conductor of heat. As a result, the heat transfer from the heat source to the heat sink is severely hindered. However, thermal conductivity silicone film has the characteristic of high compression ratio, which can expel air and ensure full contact between the heat sink and the heat source, thereby reducing the temperature of the product and ensuring its normal operation. Today, as a manufacturer of thermal conductivity silicone film Lintech Materials, we will explain the correct installation and use of thermal conductivity silicone film in 7 steps.

Keep the contact surfaces between electronic components and thermal conductivity silicone film clean, avoiding any dirt or stains on the surfaces, as they can reduce the self-adhesiveness and thermal conductivity of the silicone film.

When handling large-sized thermal conductivity silicone film, it should be grasped from the middle area, while the requirements for grasping smaller-sized sheets are not as strict. Uneven force distribution on large pieces can cause deformation, and thinner silicone film can be easily damaged.

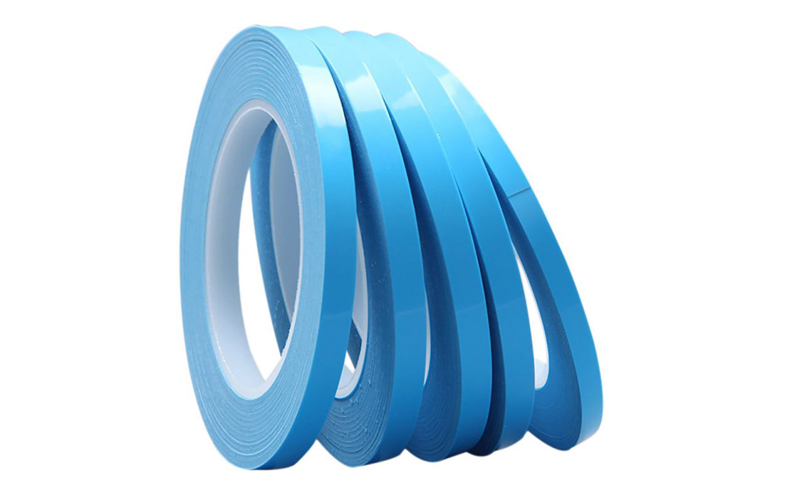

Hold the thermal conductivity silicone film with your left hand and peel off one side of the protective film with your right hand. Remember not to peel off both sides of the protective film at the same time, and try to minimize direct contact with the silicone film to prevent damage to its self-adhesiveness and thermal conductivity.

After peeling off one side of the protective film, align it with the direction of the heat sink and the electronic component to be attached. Slowly lower the thermal conductivity silicone film. It is better to use a flat sheet and push it from left to right to avoid the formation of bubbles in the middle.

If bubbles occur during the operation, lift one end of the thermal conductivity silicone film and repeat the above steps, or gently remove the bubbles with a rigid plastic sheet. Be careful not to apply excessive force to avoid damaging the silicone film.

Peel off the other side of the protective film, align it with the heat sink, and then peel off the last side of the protective film gently to avoid scratching or pulling up the thermal conductivity silicone film, which may cause bubbles to form.

After fastening or using high-adhesive thermal conductivity silicone film, apply a certain amount of pressure to the heat sink and let it sit for a period of time to ensure that the thermal conductivity silicone film is securely fixed.

Thermal conductive silicone film is already a common material, because it is very convenient to use this material, probably a glance at the instructions for the use of thermal conductive silicone film know what it is, how to operate? It is very easy to do it by yourself. The following is a description of the specific steps to use the material.

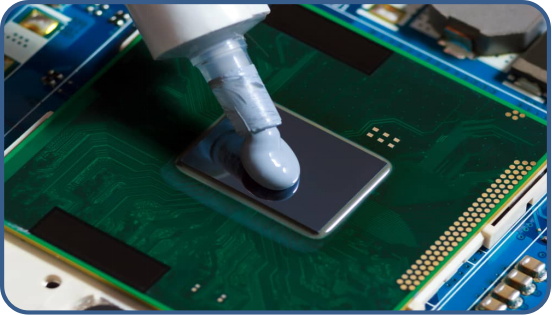

Do a good job of cleaning the surface, every family will use to electronic equipment, such as computers, computers, in the use of a long time, the host will be hot, sometimes poor heat dissipation will make their own computer lag phenomenon. The use of thermal conductive silicone film, will avoid these phenomena, in the use of the most important point is the need to clean the use of parts, if it is said to have dust or impurities, it will affect the role of the material.

Pay attention to the even application, in the use of thermal conductive silicone film, must bear in mind that the application in the even. You can borrow some small tools. For example. You can buy some small spatula in the hardware store, or a small scraper for applying paint. Use a small scraper to apply the material evenly. The material is good or bad painted on a glance can be seen, good material painted on after very smooth.

Do a good check, pay attention to the details, after the use of thermal conductive silicone film, you can check whether the coating is even, because this material. In the coating thickness is also a requirement. Can not exceed three millimeters, once more then the thermal conductivity will be reduced. Also check it. There is no bubble generation, only after careful inspection will let the material show the most perfect efficacy.

The operation of the thermal conductive silicone film is not difficult, as long as you follow the instructions to operate before installation, as long as the operation process is careful, then it is a very simple matter, but also allows the service life of household appliances to be extended.