News and Articles

Related Product

Share Article

Tensile strength factors of high performance thermal conductive materials

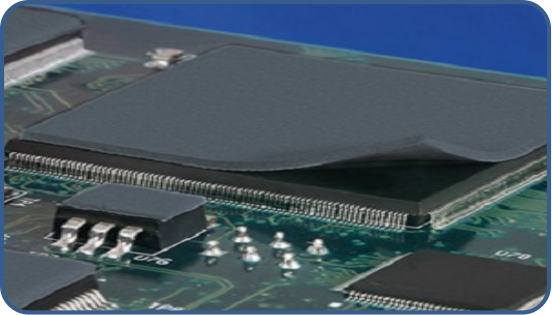

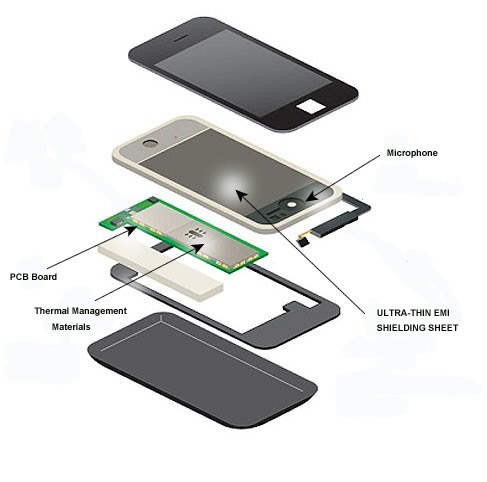

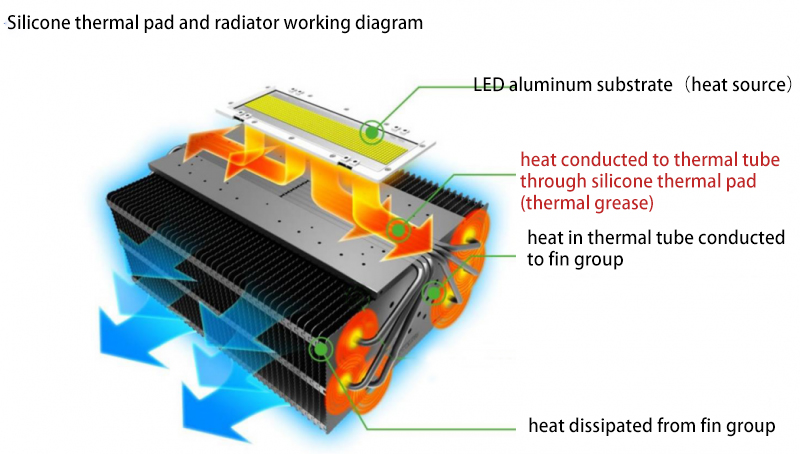

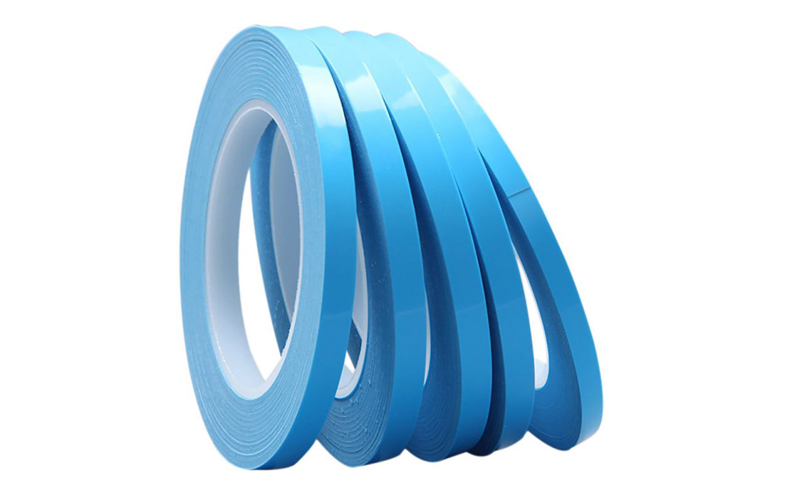

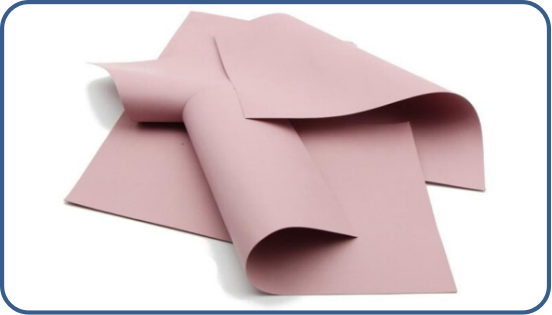

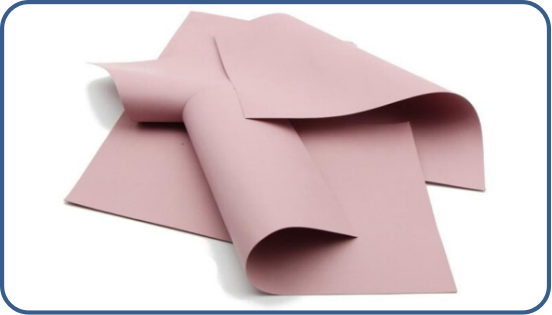

Fine Materials developed high performance thermal pad is polymer-filled material. popularly applied on electronics, automotive and LED devices. As talking about the factors that affect the tensile strength of thermal pad, we should firstly start at the origin word “polymer”.

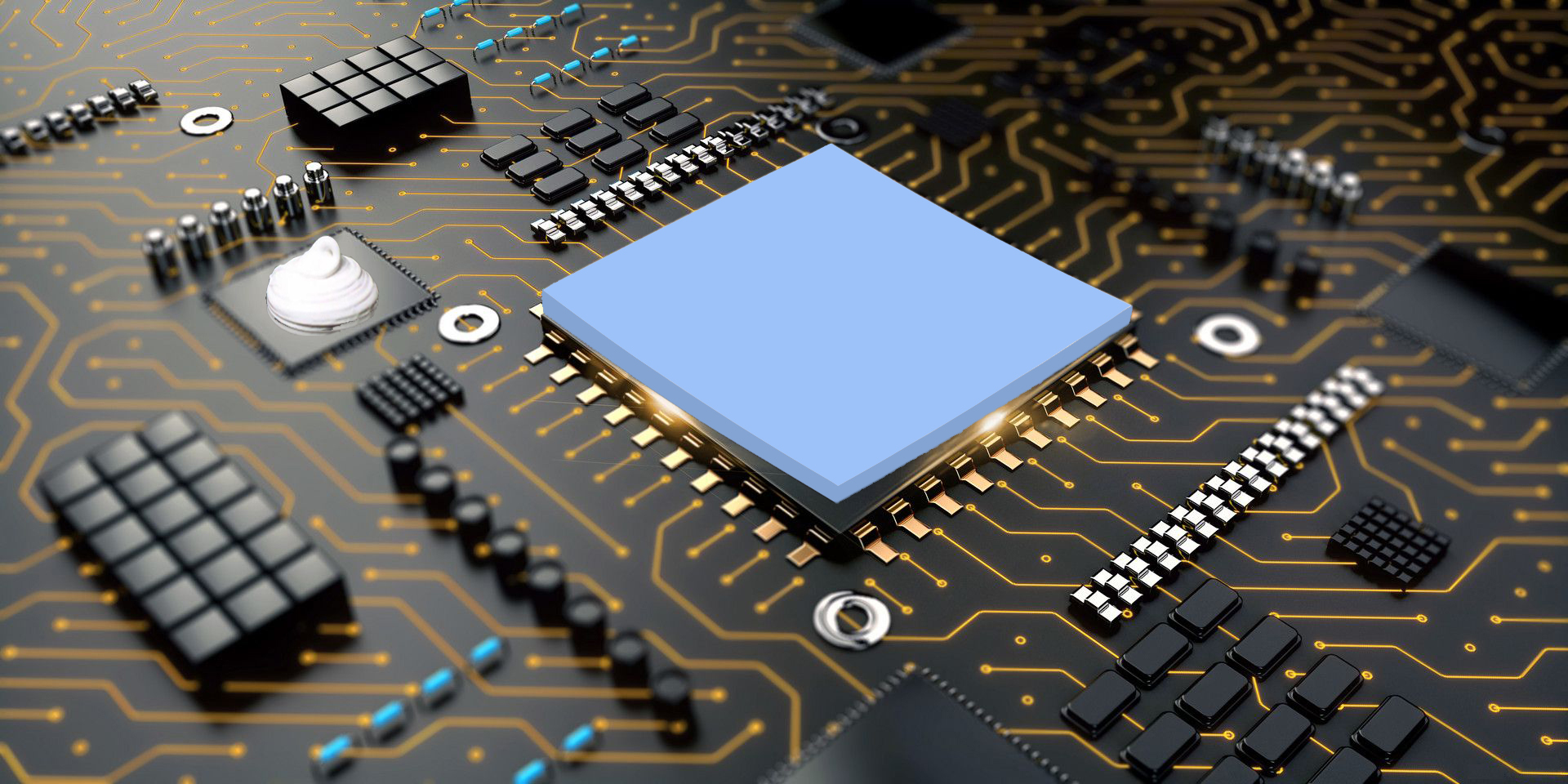

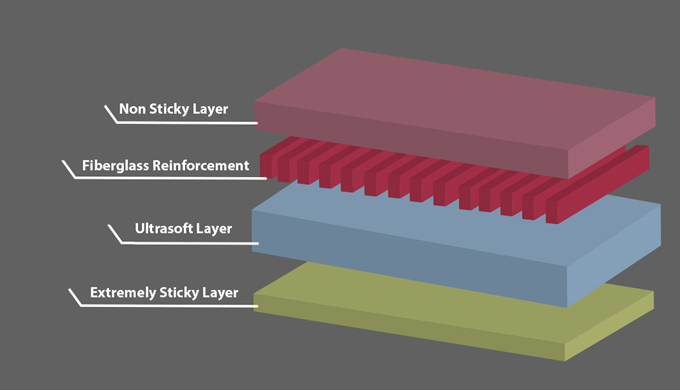

Owing to excellent electrical insulation of polymer, it has been extensively used as packing materials in electrical devices due to their good process ability, light weight and low cost. Nevertheless, the thermal conductivity of polymer is generally very low (i.e. 0.10–0.25 W/m–1·K–1), and it has been widely recognized that the thermal conductivity of these polymers has to be enhanced to lower the energy loss and increase the stability of the devices. With the increasing demand for high density power and energy transmission of electronic devices, fabrication of insulating polymer materials with high thermal conductivity has become crucial. High crystallization and orientation of polymer can greatly enhance the thermal conductivity along the orientation direction, but they usually have difficulties of processing. Blending of polymer with inorganic fillers is an effective and convenient way to enhance the polymer thermal conductivity while maintaining the electrical insulation, such as polymer composites with boron nitride (BN), aluminum nitride (AlN), silicon nitride (Si3N4), alumina, silicon carbride (SiC) and silica (SiO2) etc. have been in years’R&D from Sinoguide Technology . In the inorganic filler/polymer composites, the thermal conductivity increases with the filler content. Very high filler loading is often used to obtain high thermal conductivity. However, it seriously alters the polymer component and can form agglomerates, which induces stress concentration and decrease of the tensile strength, modulus and ductility of the material.

Filler size and shape are also important factors for the thermal conductivity and mechanical properties of the thermal conductive material. The R&D team from Sinoguide Technology used Al2O3 at different sizes to fill into thermal pad, and eventually find that nano-sized Al2O3 composite exhibited superior thermal conductivity and mechanical properties than the micro-sized one. The particle size and content in the composite govern the average interparticle gap, which is associated with the thermal conductivity and mechanical properties. At the same particle content, smaller particle size heads to lower interparticle distance and more chances for the formation of thermal pathway. The particle size and content affect the interparticle distance and the stress state of the matrix polymer surrounding the voids. When the average interparticle distance is in a suitable range, extensive plastic deformation in the matrix can be easily induced. Accordingly, the optimization of the particle size and content can be a convenient and feasible way to prepare composites with good synthetic properties for the thermal conductive materials.

Fine Materials has been bringing world-class science and engineering to the global marketplace in the form of innovative products, materials, and services since its established.