News and Articles

Related Product

Share Article

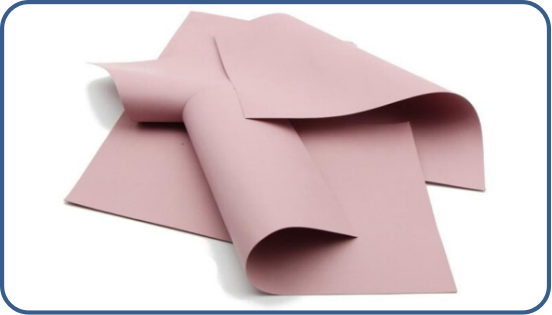

What is Thermally Conductive Silicone Sheet

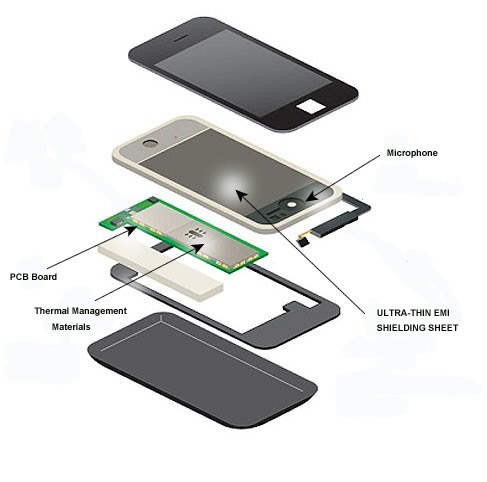

"Thermally conductive silicone sheet" is based on silica gel, add metal oxides and other auxiliary materials, through a special process of synthesis of a thermally conductive media materials, in the industry, also known as thermal conductive silicone pad, thermal conductive silicone sheet, soft thermal pad, thermal conductive silicone gasket, etc., is specifically designed for the use of the gap to transfer the heat of the design of the production program, can fill Gap, through the heat-generating parts and heat dissipation parts of the thermal channel between the effective enhancement of the heat transfer efficiency, but also play a role in insulation, shock absorption, sealing, etc., to meet the miniaturization of the equipment and ultra-thin design requirements, is a great craftsmanship and usability, and the thickness of the application of a wide range of an excellent thermal conductivity of the filler material.

Thermally Conductive Silicone Sheet Materials Advantages

1, the material is softer, good compression properties, good thermal conductivity and insulation properties, the thickness of the adjustable range is relatively large, suitable for filling the cavity, both sides of the natural viscosity, operability and maintenance;

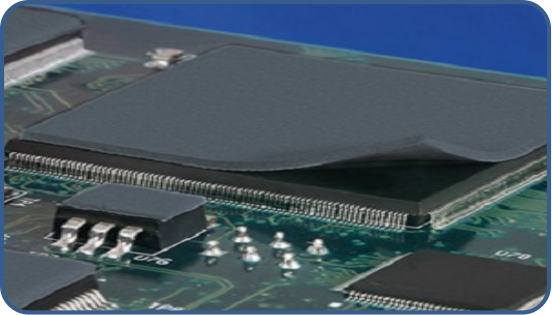

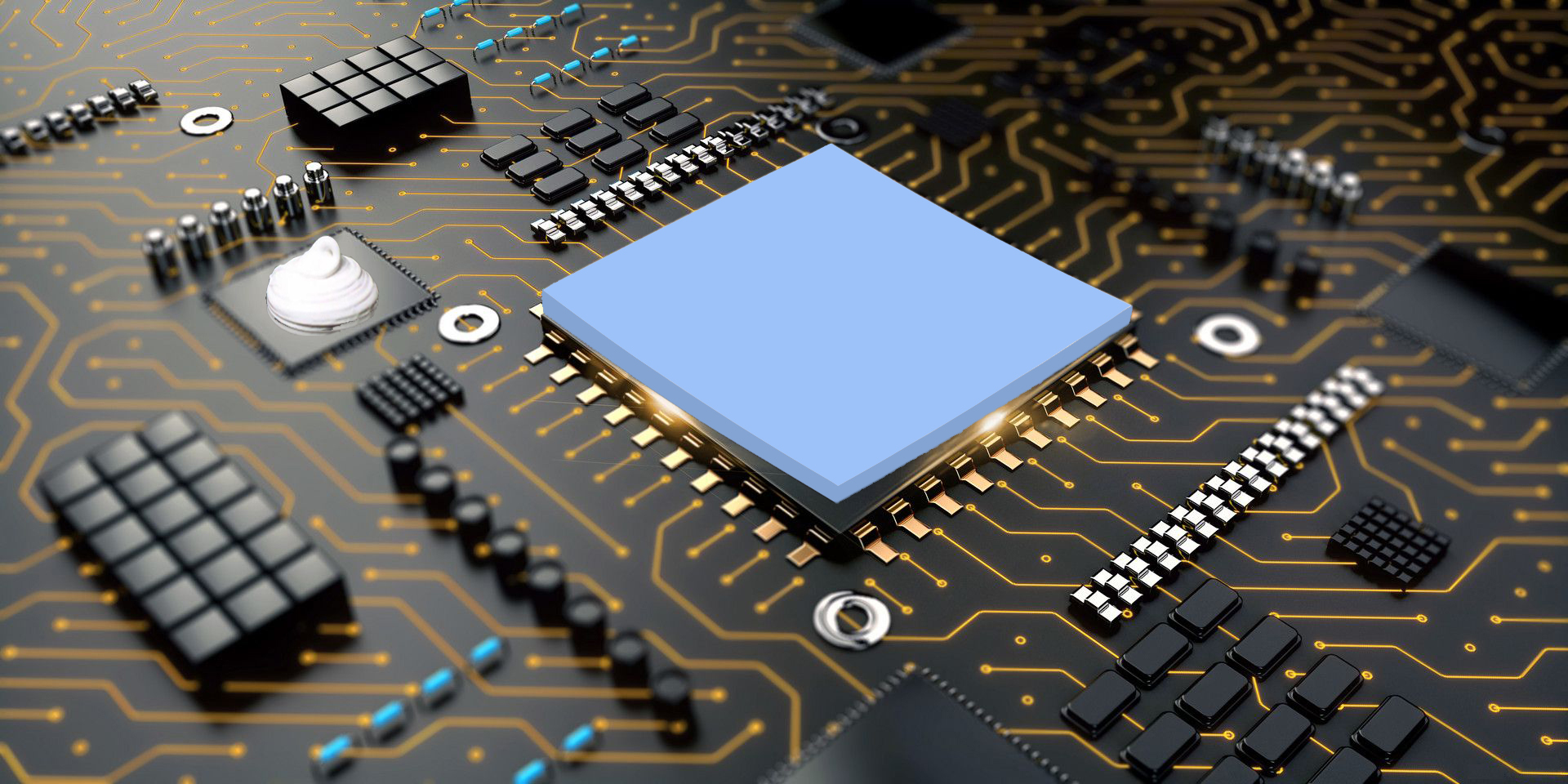

2, the selection of thermally conductive silicone sheet of the most important purpose is to reduce the surface of the heat source and the contact surface of the radiator pieces of contact between the contact thermal resistance, thermally conductive silicone sheet can be very good to fill the gap between the contact surface;

3, because the air is a poor conductor of heat, will seriously impede the transfer of heat between the contact surfaces, and in the heat source and heat sinks installed between the thermal conductive silicone film can be extruded out of the air contact surface;

4, with the addition of thermal conductive silicone film, can make the heat source and heat sink between the contact surface of the better full contact, the real face-to-face contact. The reaction in temperature can be achieved as small as possible temperature difference;

5, the thermal conductivity of the thermal conductivity of the silicon film has adjustable, thermal stability is also better;

7, thermally conductive silicone film in the structure of the process of bridging the gap, reducing the heat sink and heat dissipation structural components of the process of work requirements;

8, thermal conductive silicone sheet with insulation properties (the characteristics of the production of the need to add the appropriate materials);

9, thermally conductive silicone sheet with shock absorption effect;

10, thermal conductive silicone sheet with installation, testing, reusable convenience.

Thermally Conductive Silicone Sheet Disadvantages

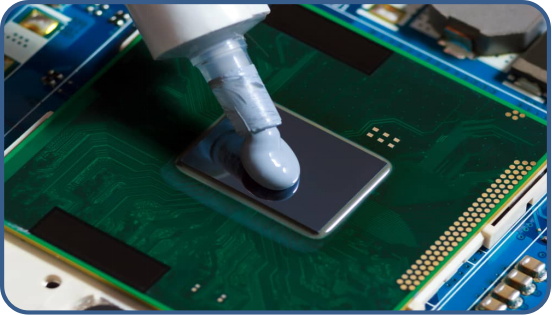

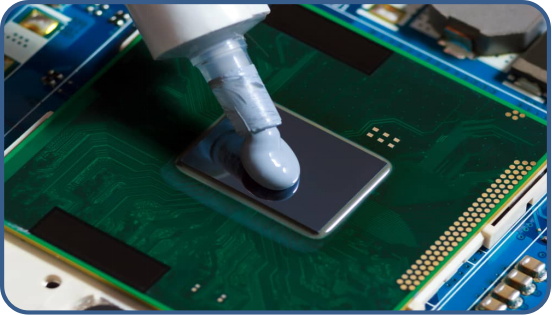

Relative to thermally conductive silicone grease, thermally conductive silicone gel has the following disadvantages:

1, although the coefficient of thermal conductivity is higher than that of thermally conductive silicone, but the thermal resistance is also higher than that of thermally conductive silicone.

2, the thickness of 0.5mm below the thermal conductive silicone sheet process is complex, the thermal resistance is relatively high;

3, thermally conductive silicone grease temperature range is greater, they are thermally conductive silicone grease -60 ℃ ~ 300 ℃, thermally conductive silicone sheet -50 ℃ ~ 220 ℃;

4, price: thermally conductive silicone grease has been commonly used, the price is lower, thermal conductive silicone sheet more applications in laptop computers and other thin and small precision electronic products, the price is slightly higher.

Thermally Conductive Silicone Sheet Widely Used

Used in electronic and electrical products, control motherboards, motor internal and external pads and feet, electronic appliances, automotive machinery, computer mainframes, laptops, DVDs, VCDs and any other materials that need to be filled as well as heat dissipation module.

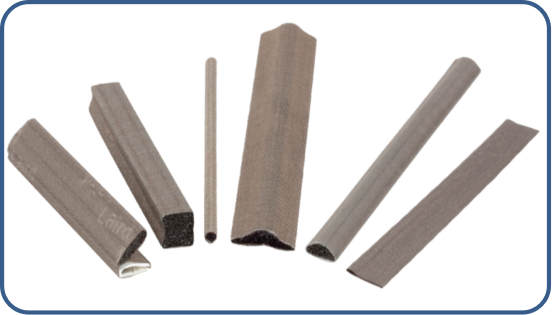

Thermal Silicone Sheet Main Classification

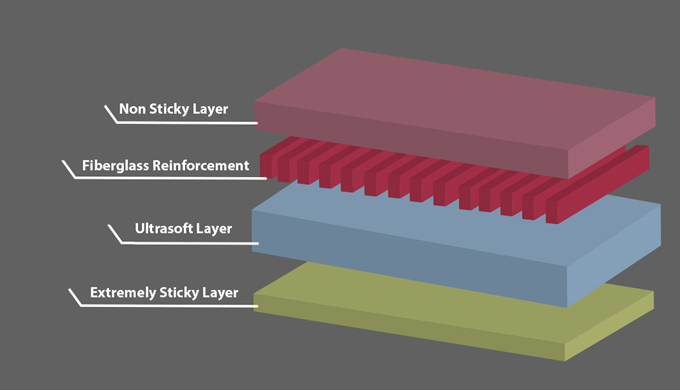

Ordinary thermally conductive silicone sheet, strong adhesive thermally conductive silicone sheet, back silicone tape thermally conductive silicone sheet, the middle with glass fiber thermally conductive silicone sheet. Domestic thermal conductivity silicone sheet thermal conductivity from 0.8W/M.K ~ 12.0W/M.K, thermal conductivity of the test standard has three, different test standards will be different data, etc. ....

Thermally Conductive Silicone Sheet Specification

| Typical Properties of Lintech Thermal Conductive Sheet | ||||||||||

| Properties | Units | TCP100 | TCP150 | TCP200 | TCP300 | TCP500 | TCP600 | TCP750 | TCP110U | Test Method |

| Color | --- | Gray | Black | Dark Gray | Blue | Pink~Violet | Light Blue | Violet | pink/white | Visual |

| Reinforcement Carrier | --- | — | — | — | — | — | — | — | Fiberglass | --- |

| Thickness Range | mm | 0.25~15 | 0.25~15 | 0.25~15 | 0.25~15 | 0.25~15 | 0.3~10 | 1.0~10 | 0.5~10 | --- |

| natural tacky (1- or 2-sided) | --- | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 1 | --- |

| Hardness | Shore C | 25,35 | 15,25,35 | 15,25,35 | 25,35 | 30 | 30 | 50 | 5, 15 | ASTM D2240 |

| Density | g/cc | 1.8 | 2.2 | 2.4 | 2.6 | 3 | 3.6 | 3.8 | 2.0 | ASTM D792 |

| Continuous Use Temp | ℃ | -40 to 200 | EN344 | |||||||

| ELECTRICAL | ||||||||||

| Breakdown Voltage | Kv/mm | ≥9 | ≥9 | ≥9 | ≥6.0 | ≥6.0 | ≥6.0 | ≥6.0 | ≥6.0 | ASTM D149 |

| Volume Impedance | ohm-cm | ≥4x1012 | ≥5x1012 | ≥3.6x1013 | ≥1.1X1014 | ≥1.1X1014 | ≥6.5X1010 | ≥6.5x1010 | ≥6.2X1015 | ASTM D257 |

| Dielectric Constant | 1MHz | 5.27 | 5.2 | 6 | 6.8 | 6.6 | 6.5 | 6.8 | 5.5 | ASTM D150 |

| Flame Rating | --- | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 | UL 94 |

| THERMAL | ||||||||||

| Thermal Conductivity | W/m.k | 1.0 | 1.5 | 2.0 | 3.0 | 5.0 | 6.0 | 7.5 | 1.1 | ASTM D5470 |

Thermal Conductive Sheet Applications

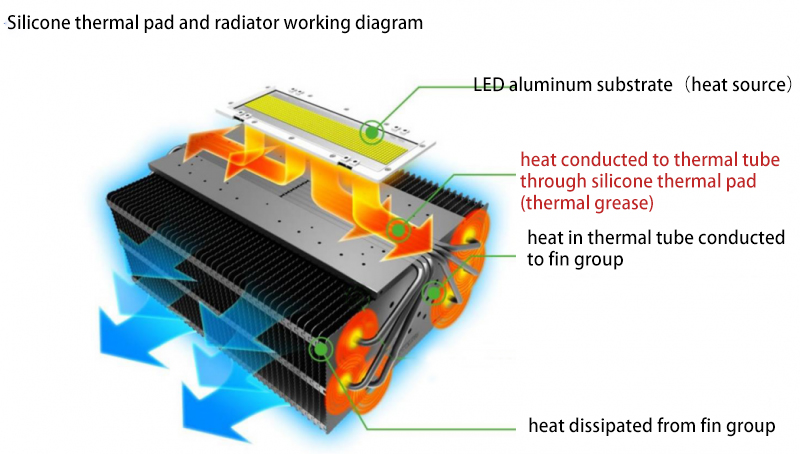

◆Thermal Conductive Silicone Sheet for LED Industry

Thermally conductive silicone sheet is used between aluminum substrate and heat sink.

◆Power supply industry

Used for thermal conductivity between MOS tube, transformer (or capacitor/PFC inductor) and heat sink or shell.

◆Communication industry

TD-CDMA products in the motherboard IC and heat sink or shell between the thermal conductivity TD-CDMA products between motherboard ICs and heat sinks or housings

● Heat conduction between DC-DC IC of set-top box and its case.

◆Applications in the automotive electronics industry

Automotive electronics industry applications (such as xenon ballasts, audio, car series products, etc.) can be used to thermal conductive silicone sheet.

◆PDP / LED TV applications

Amplifier IC, image decoder IC and the heat sink (shell) between the thermal conductivity

◆Home appliance industry

Microwave oven/air conditioner (between fan motor power IC and shell)/Induction cooker (between thermistor and heat sink)